Your launchpad to the orbital economy

From idea to orbit

ORLaunch is the gateway into the new space economy – a digital platform that empowers entrepreneurs, innovators, and investors to design, fund, and launch orbital ventures. From concept to execution, ORLaunch transforms complex space business development into a structured, intelligent, and collaborative process.

Three ways ORLaunch accelerates your mission

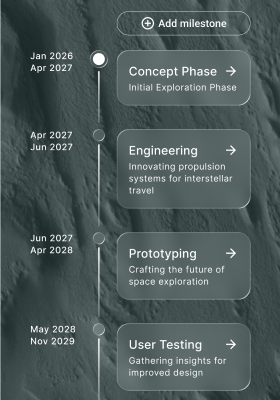

Transform ideas into executable ventures

Turn early-stage concepts into fully structured business plans. ORLaunch guides users through validation, technical scoping, and milestone planning – producing a clear roadmap from idea to orbital deployment.

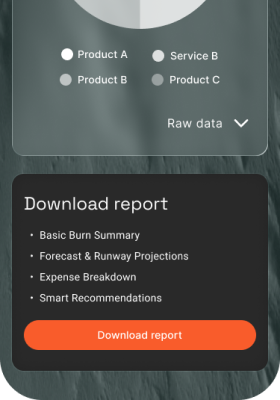

Generate investor-ready materials instantly

Build professional-grade documentation, visuals, and financial projections in minutes. AI-driven templates generate the pitch decks, 3D models, and cost structures investors need to evaluate and fund your project – reducing months of preparation to hours.

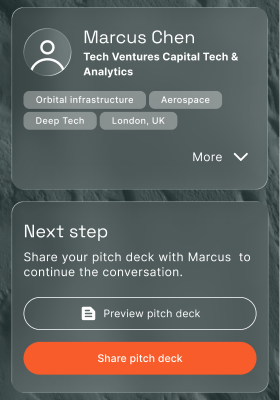

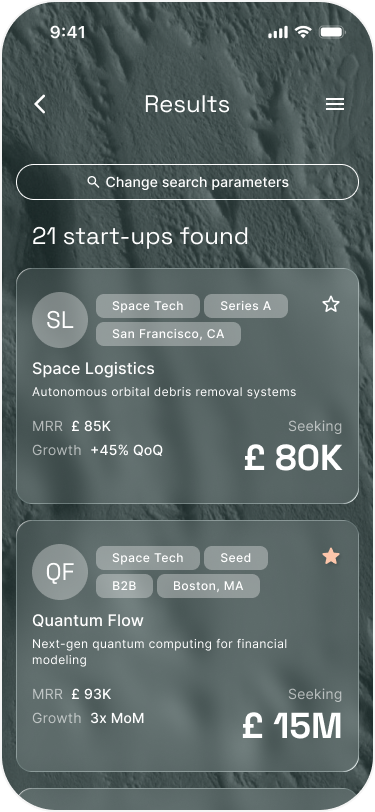

Connect with global partners and capital

Access an international ecosystem of investors, accelerators, and technical advisors.

Find co-founders, suppliers, and financiers within a curated network built around verified credentials and shared strategic goals.

Powered by AI and orbital intelligence

ORLaunch isn’t a static template - it’s an adaptive co-pilot that learns your business. It integrates real orbital data, launch schedules, debris mitigation parameters, and regulatory frameworks to build realistic, dynamic financial models.

Dynamic modeling

Factors in launch windows, insurance, and compliance costs.

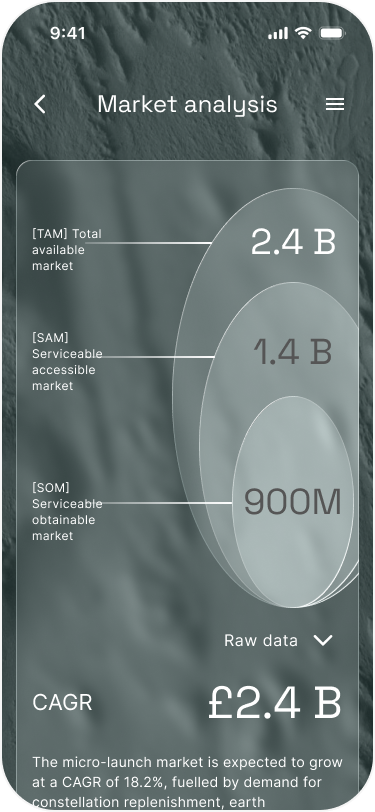

Market intelligence

Maps sector trends, pricing, and competitive positioning.

Smart networking

Verifies partners and connects ventures to relevant investors and agencies.

Who it’s for

Whether you’re an engineer with a breakthrough design, an entrepreneur building a space company, or a fund manager assessing opportunities – ORLaunch bridges innovation and investment.

It turns ambition into action, and ideas into enterprises ready for orbit.

Ready to launch your space venture?

Access to the orbital economy has never been this direct.

Join the innovators building humanity’s next frontier.